Lighting Cabinet, Multi-channel LED, Daylight & Blackbody Simulator, Image Evaluation, Camera Calibration, Visual Assessment

How Cameras “See True Color” — Exploring the Critical Role of Multi-Channel LED Calibration Light Sources in Camera Production Lines

Why Do Cameras “See Colors Wrong”?

Have you ever noticed that two cameras capture the same scene with noticeably different colors? One of the main reasons lies in the light source used during production and testing. A camera’s “eyes” — its image sensors — are highly sensitive to light. If the spectral power distribution (SPD) of the test light source is unstable, the camera may misinterpret colors or brightness. That’s why controllable, spectrally stable light sources are essential in both camera production lines and laboratories. Among these, multi-channel spectrally tunable LED light sources are increasingly adopted by manufacturers and research institutions for their ability to accurately reproduce different spectra.

↑Two cameras capture the same scene with noticeably different colors.

Light and Camera Calibration: A Battle Between “Reality” and “Deviation”

To enable a camera to see true color, several key aspects must be standardized:

1.Spectral Power Distribution (SPD)

The spectrum is the “fingerprint” of light, defining energy across different wavelengths. If the spectrum deviates, red may appear pink, and blue may turn violet.

→ Therefore, camera calibration must be performed under a known and controllable SPD.

2.Color Temperature and Color Rendering

You may have noticed how photos look warmer under yellow light and cooler under white light. Cameras must learn to reproduce colors accurately under varying color temperatures.

→ Scientific testing requires adjustable and precise color temperature control.

3.Illuminance and Uniformity

Imagine shining a flashlight on a test chart — bright in the center but dark at the edges. The uneven illumination will cause calibration errors.

→ Calibration light sources must provide large-area, uniform illumination.

4.Long-Term Stability

A production line may test tens of thousands of camera modules per day. If light output drifts over time, large-scale errors occur.

→ Stability and lifespan are therefore equally crucial.

These requirements have already been defined in international standards:

● ISO 14524: OECF (Opto-Electronic Conversion Function) testing must be conducted under uniform illumination.

● ISO 17321: Camera color characterization must use standardized light sources.

● IEC 62471: Light sources must comply with photobiological safety evaluations.

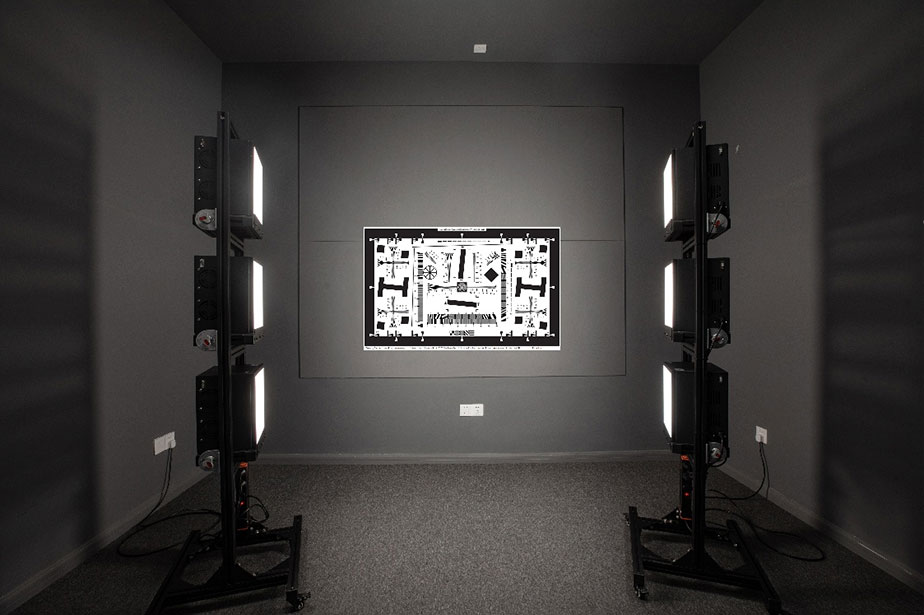

How Calibration Light Sources Work on Camera Production Lines

Imagine a smartphone factory testing thousands of camera modules daily. The process typically involves:

1.Activating a standard light source that meets requirements for illuminance, color temperature, and spectral profile;

2.Placing grayscale or color charts in front of the camera for image capture;

3.Collecting data to correct white balance and color matrices;

4.Repeating tests to ensure consistent performance across modules under different lighting conditions.

If the light source is unstable, test results will vary — causing visible color differences among cameras from the same batch. Hence, spectrally tunable LED light sources have become the preferred solution. They enable rapid switching between spectral scenes, ensuring that every camera is calibrated under identical and traceable lighting conditions.

Thouslite’s Educational Contribution: Turning Standard Light Into a Learning Tool

In this field, Thouslite’s multi-channel LED systems are widely used not only for their performance but also for their educational and scientific value — helping researchers, engineers, and students understand how spectra influence imaging.

● LEDPanel

A compact, high-precision light source with adjustable color temperature (2800–6500 K) and storable spectral recipes. Commonly used in camera module production lines.

● LEDTrans

A large-area transmissive light box offering >96% uniformity and up to 18,000 lux brightness — ideal for full-system camera testing and large-format chart illumination.

● LEDView

A laboratory-grade standard light box capable of reproducing various spectral trajectories, widely used for research and algorithm validation.

● LEDCube

A high-channel mixed-light system capable of simulating daylight, indoor lighting, or even automotive headlights — supporting realistic scene testing.

In education and research, these light sources serve as “virtual laboratories,” offering an intuitive way to explore the intricate relationship between spectrum, color, and imaging.

Future Outlook: The Age of AI and the Quest for “True Color”

As AI-driven photography and machine vision evolve, the importance of controllable light grows rapidly:

● AI Camera Training: Algorithms require standardized lighting for data collection; otherwise, models risk color bias.

● Cross-Factory Consistency: Global production lines of the same camera brand rely on standard light sources to ensure uniform output.

● Complex Scene Simulation: From nighttime driving to low-light surveillance, systems like LEDCube can replicate real-world lighting for testing and training.

↑LEDCube - Any SPD Simulator

In short, the intelligence of future cameras will depend on the standardization of light.

Conclusion: Teaching Machines to See True Color Is Teaching Humans to See Truth

Cameras are extensions of human vision. Spectrally tunable LED calibration light sources are, in essence, their “teachers,” helping these mechanical eyes recognize color correctly. Through years of expertise in spectral control, Thouslite not only provides reliable industrial tools but also a platform for education and research. It reminds us that in the evolution of imaging technology, light is more than illumination — it is the guardian of true color.

About Thouslite

Thouslite specializes in the development and application of spectrally tunable LED and optical calibration technologies, providing high-precision standard lighting solutions for imaging, machine vision, and color science. Its product portfolio—covering multi-channel tunable light sources, spectral simulation systems, and visual evaluation equipment—is widely adopted by global research institutions and advanced manufacturing industries. With deep expertise in spectral control and colorimetric measurement, Thouslite continues to advance the standardization and quantification of light environments, bridging the gap between scientific accuracy and real-world visual experience. For more information, please visit: www.thouslite.com